Product & Service

Product & Service

Wire Harness

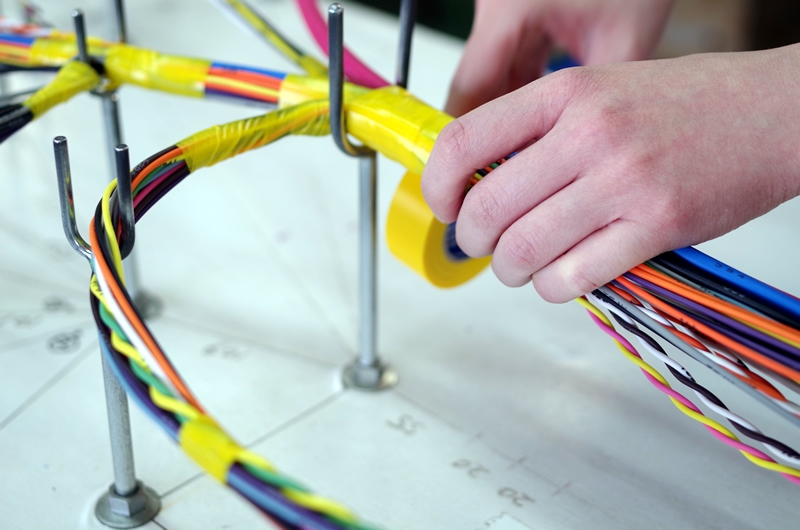

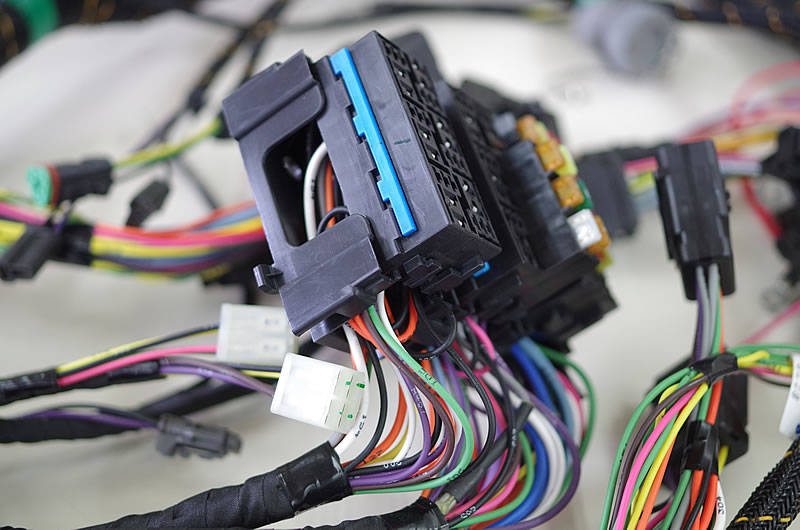

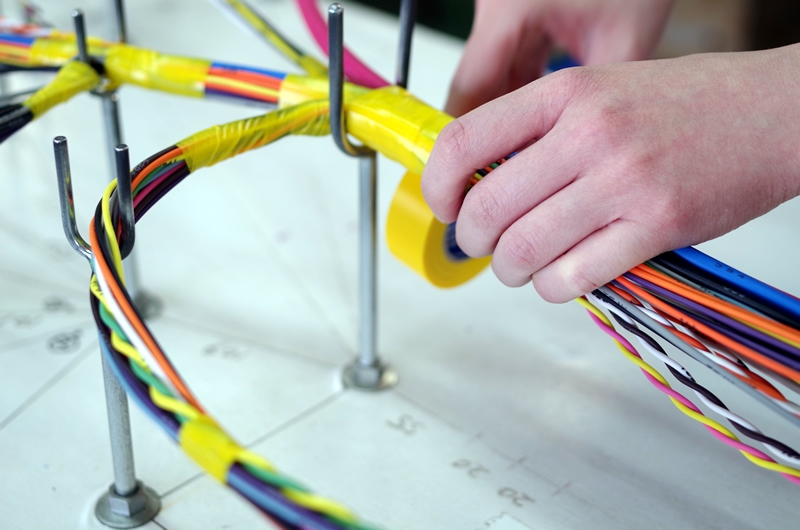

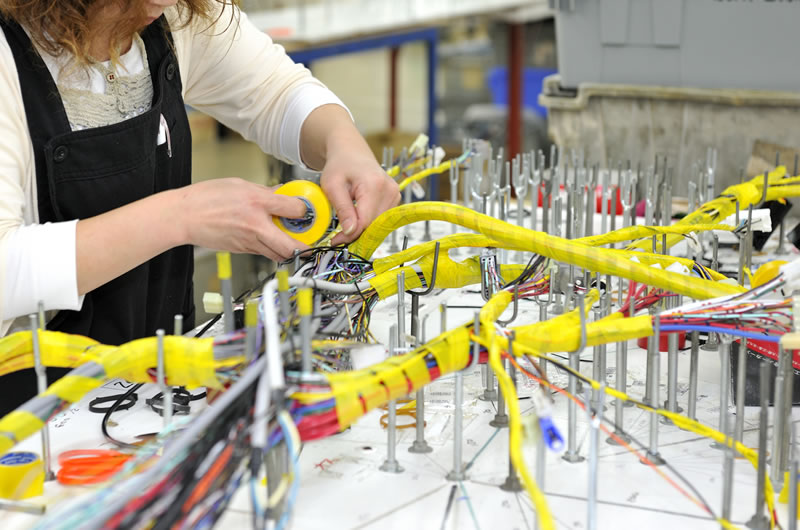

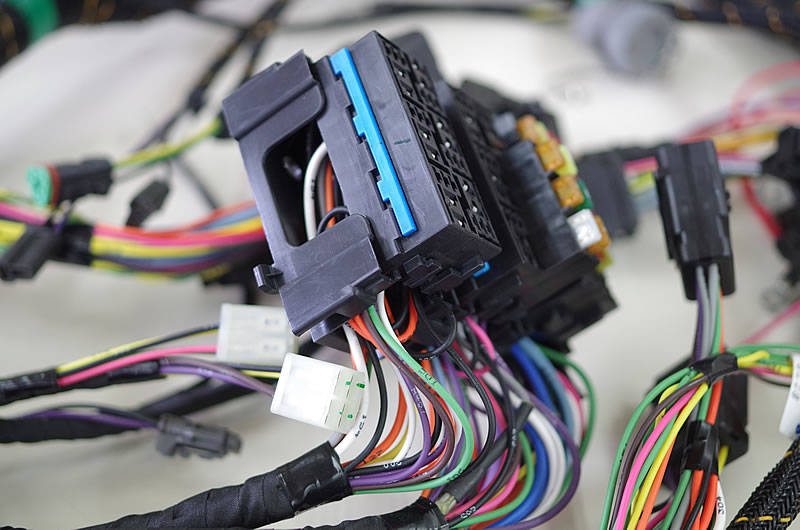

Wire harness, which is installed in various familiar equipment, play an important role to convey electric power and signals. Especially, our wire harnesses are used as parts of vehicles, construction machines, industrial vehicles and industrial equipment.

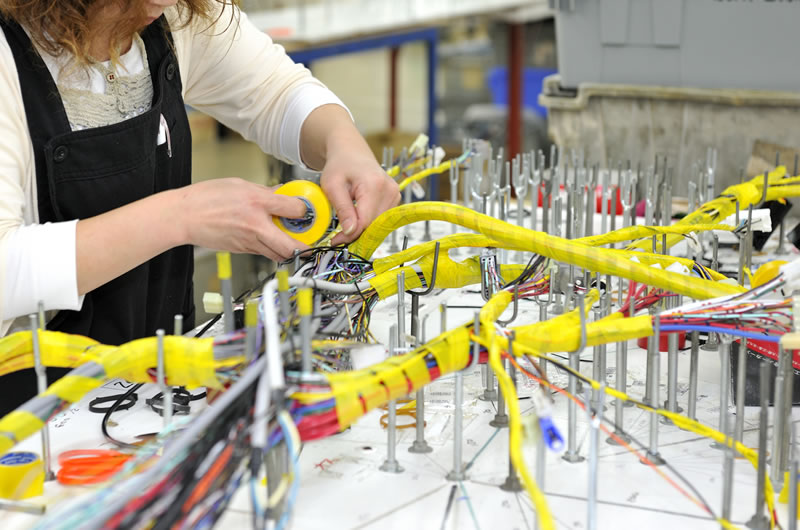

With high technology cultivated in our long history and the latest equipment, we manufacture products diversifying with the times such as small circuit harness, large wire harness over 500 circuits, specialized wire harness capable of withstanding harsh environments to respond to customer’s need.

Our knowhow unique to electric wire manufacturer and a wide variety of processing equipment such as terminal crimping applicators enable us to manufacture from 1 piece to mass production.

We have already prepared a production environment to meet customer’s requests. Because of having factories in Japan and overseas, we can response to all requirements quickly and struggle with cost competition.

In order to maintain high quality, we perform the inspection that meets the customer’s strict quality standard and our internal standard in each process. Also, if some troubles are happened, we pursue the cause thoroughly and feedback the result to each process. We always cooperate with domestic and overseas factories, and delivery our products to customer with the best quality.

If you have any requests regarding wire harness, such as making prototype, sudden design change and response to short lead time, please contact us.

Wire & Cable

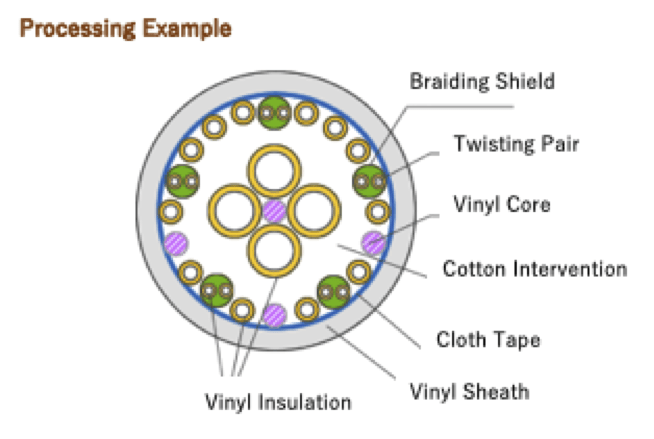

We product various kinds of electric wires and cables. Our manufacturing result of those products in response to customer’s requests are kinds of 3,000 or more.

We can manufacture electric wires using the customer-selected wire size, insulation material and sheath material.

It is possible to select colorful sheath for production of vinyl cable, such as blue, yellow, red, white and other colors besides gray and black usually used. For processing insulated cables, not only single color but also stripe color processing is available.

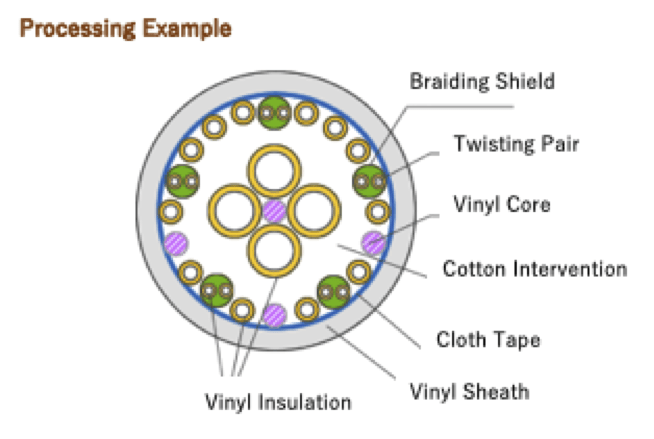

In the case of multi-core cable, processing for various specifications is possible, for example, combining wires of the different size, making distinctions by sheath color, numbering processing, shield processing and so on. In addition, it is possible to make up several wires you have into one cable.

We will provide the most suitable electric wires with customized specification according to the requirements of customers

Processable Material Item

Wire

Naked

0.05 A 〜 0.45 A

0.05 TA 〜 0.45 TA

Vinyl, Polyethylene, Silicone rubber

Vinyl, Polyethylene

Processable Material Item

Twist Processing

Tubular Extrusion

Processing size

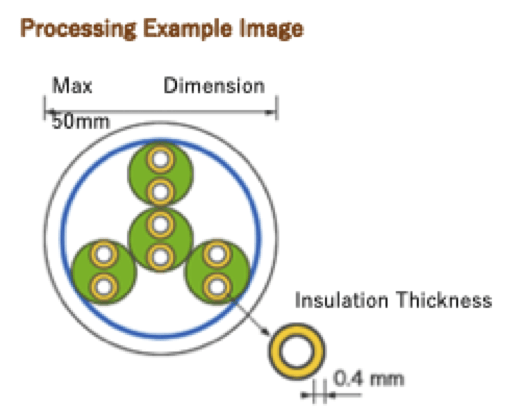

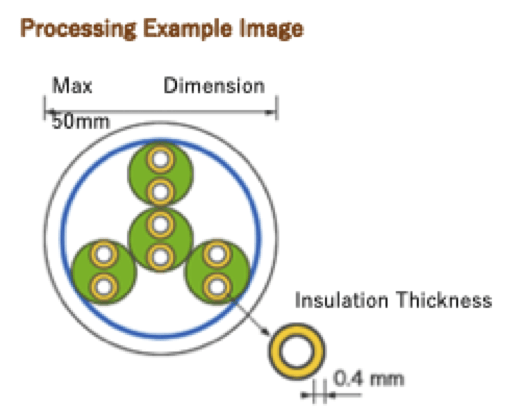

Maximum diameter : 50mm

Covered Wires Production Flow

▼

- pressure-resistant

- insulation etc.

▼

- Vinyl

- Polyethylene

- Silicone Rubber-Check the cable using environment (temperature / weather)

▼

- No shield

- Spiral Shield (whole or separate)

- Braided Shield

▼

▼

▼

▼

Production Flow of Bare Wires

▼

Choose the kind of core wire

- Check the flexibility

▼

▼

▼

▼

Others: Wire Processed Product

Our wire processed products are used for railway infrastructure, manufacturing machines, construction machines, information equipment and so on. By consistently carrying out designing, manufacturing and machining, it is possible to respond widely to customer’s needs such as advanced technology products and small lot multi varieties production.

For example, we manufacture heat-resistant cables using the extruder dedicated to silicone rubber and the vulcanizing furnace. We also perform silicone coating processing on high strength rope using these facilities. This product is adopted for outdoor use.

Besides, it is possible for us to make terminals compression processing for large size cable from 125sq to 600sq.

If there is anything that we can help you, please do not hesitate to contact us.

Wire Harness

Wire harness, which is installed in various familiar equipment, play an important role to convey electric power and signals. Especially, our wire harnesses are used as parts of vehicles, construction machines, industrial vehicles and industrial equipment.

With high technology cultivated in our long history and the latest equipment, we manufacture products diversifying with the times such as small circuit harness, large wire harness over 500 circuits, specialized wire harness capable of withstanding harsh environments to respond to customer’s need.

Our knowhow unique to electric wire manufacturer and a wide variety of processing equipment such as terminal crimping applicators enable us to manufacture from 1 piece to mass production.

We have already prepared a production environment to meet customer’s requests. Because of having factories in Japan and overseas, we can response to all requirements quickly and struggle with cost competition.

In order to maintain high quality, we perform the inspection that meets the customer’s strict quality standard and our internal standard in each process. Also, if some troubles are happened, we pursue the cause thoroughly and feedback the result to each process. We always cooperate with domestic and overseas factories, and delivery our products to customer with the best quality.

If you have any requests regarding wire harness, such as making prototype, sudden design change and response to short lead time, please contact us.

Wire & Cable

We product various kinds of electric wires and cables. Our manufacturing result of those products in response to customer’s requests are kinds of 3,000 or more.

We can manufacture electric wires using the customer-selected wire size, insulation material and sheath material.

It is possible to select colorful sheath for production of vinyl cable, such as blue, yellow, red, white and other colors besides gray and black usually used. For processing insulated cables, not only single color but also stripe color processing is available.

In the case of multi-core cable, processing for various specifications is possible, for example, combining wires of the different size, making distinctions by sheath color, numbering processing, shield processing and so on. In addition, it is possible to make up several wires you have into one cable.

We will provide the most suitable electric wires with customized specification according to the requirements of customers

Processable Material Item

Wire

Naked

0.05 A 〜 0.45 A

0.05 TA 〜 0.45 TA

Vinyl, Polyethylene, Silicone rubber

Vinyl, Polyethylene

Processable Material Item

Twist Processing

Tubular Extrusion

Processing size

Maximum diameter : 50mm

Covered Wires Production Flow

▼

- pressure-resistant

- insulation etc.

▼

- Vinyl

- Polyethylene

- Silicone Rubber-Check the cable using environment (temperature / weather)

▼

- No shield

- Spiral Shield (whole or separate)

- Braided Shield

▼

▼

▼

▼

Production Flow of Bare Wires

▼

Choose the kind of core wire

- Check the flexibility

▼

▼

▼

▼

Others: Wire Processed Product

Our wire processed products are used for railway infrastructure, manufacturing machines, construction machines, information equipment and so on. By consistently carrying out designing, manufacturing and machining, it is possible to respond widely to customer’s needs such as advanced technology products and small lot multi varieties production.

For example, we manufacture heat-resistant cables using the extruder dedicated to silicone rubber and the vulcanizing furnace. We also perform silicone coating processing on high strength rope using these facilities. This product is adopted for outdoor use.

Besides, it is possible for us to make terminals compression processing for large size cable from 125sq to 600sq.

If there is anything that we can help you, please do not hesitate to contact us.